FAQs

We understand you may have questions about our services. This FAQ page provides answers to some of the most common inquiries we receive from our clients. If you have any further questions or require more specific information, please don’t hesitate to contact us. We’re always happy to assist you.

QUESTION

What are the benefits of laser cleaning?

answer

Laser cleaning is an innovative and highly effective method used for surface cleaning, material preparation, and restoration across various industries. Some of the key benefits of laser cleaning include:

- Efficient process: Laser cleaning can be very fast, often cleaning surfaces much more quickly than traditional methods. This improves efficiency in industries where downtime is critical.

- Cost-effective: laser cleaning allows for restoration eliminating the need for new purchases which can take time and money, both valuable resources.

- Increases value: the cleaning or restoration of antiques can increase their value greatly.

- Environmentally friendly and little waste: Unlike traditional methods (e.g., sandblasting or chemical cleaning), laser cleaning produces minimal waste and does not contaminate the surrounding area with pollutants.

- Precision and control for selective cleaning: Laser cleaning can be highly selective, targeting specific areas or materials.

- Wide range of applications: Laser cleaning can be applied to a variety of substates removing multiple types of material for applications like rust removal, paint stripping, surface preparation for coating, and even the cleaning of intricate parts in machinery applicable across many industries.

QUESTION

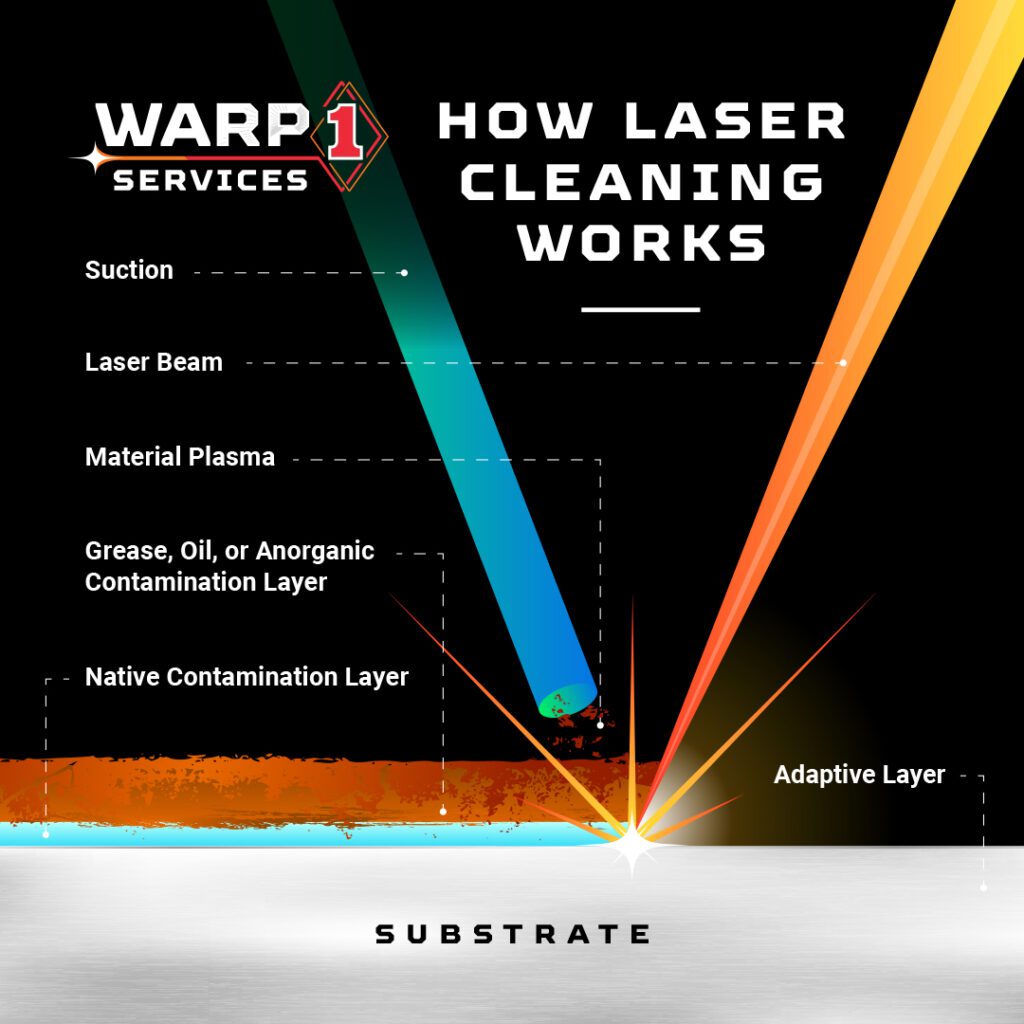

How does laser cleaning work?

answer

Laser cleaning uses a focused beam of light to vaporize contaminants from a surface without damaging the underlying material. The laser beam is directed through a fiber optic cable to a reflector system that emits the laser in the desired shape. The ultra-short laser pulses create high temperatures and pressures that evaporate impurities.

QUESTION

What services does Warp 1 offer?

answer

Warp 1 specializes in the cleaning and restoration of various materials such as metal, cast iron, and concrete. We use a laser ablation technology cleaning process capable of removing contaminants, rust, paint, and coatings. The technology and service can provide solutions for various industries such as including manufacturing, automotive, agricultural, construction, and more. Contact us to see how we can help.

QUESTION

Why Warp 1 Services?

answer

Warp 1 Services was founded with the purpose of delivering specialized restoration and maintenance solutions for both businesses and individuals. Jim’s vision is to offer a targeted service that highlights the transformative potential of laser cleaning technology. At the heart of this service is the desire to bring the old back to life, restore the dirty to pristine, and make the inoperable fully functional again—using state-of-the-art, environmentally friendly laser cleaning methods. With cutting-edge technology, Jim is dedicated to making the impossible possible, offering clients an innovative way to preserve and revitalize their assets while minimizing environmental impact.

QUESTION

How does laser ablation work?

answer

Laser ablation uses a highly focused laser beam to remove surface contaminants like rust, paint, and powder coat without damaging the underlying metal.

QUESTION

What materials can be cleaned with a laser?

answer

Laser cleaning can be used on a wide range of materials, including metals, concrete, and cast iron.

QUESTION

What types of metals can Warp 1 restore?

answer

Warp 1 can restore a wide variety of metals, including steel, aluminum, and more. Contact us to see if we can help with your specific needs.

looking for

metal Restoration

services?

For all your metal restoration needs, contact Warp 1 today. We provide expert craftsmanship and personalized solutions.